Technical Overview

A Modular Autonomous Surface Vehicle

for Research, Field Testing & Competition

TALAZ is an autonomous unmanned surface vehicle developed as a robust and scalable platform for autonomous navigation, object detection, and dynamic mission execution in constrained aquatic environments. The system unifies hydrodynamic stability, a ROS 2–driven mission autonomy stack, onboard perception, and fault-tolerant communication—enabling continuous and reliable operation for tasks such as environmental monitoring, data collection, and surveillance.

Mechanical Design & Propulsion

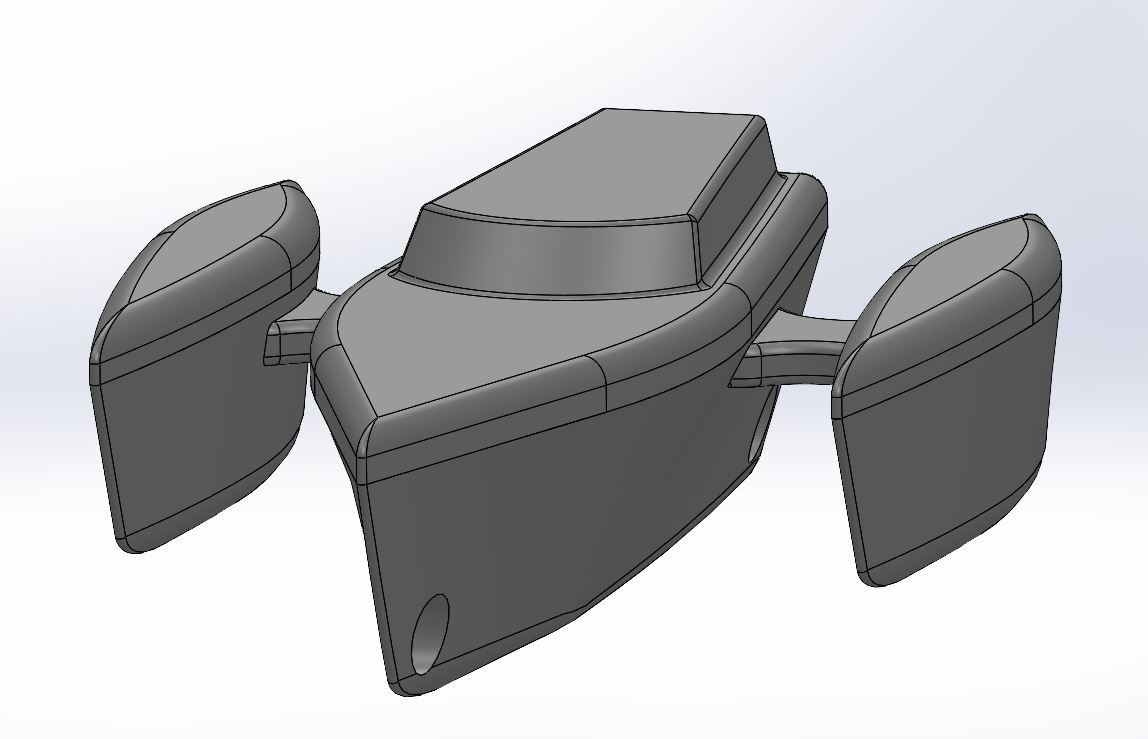

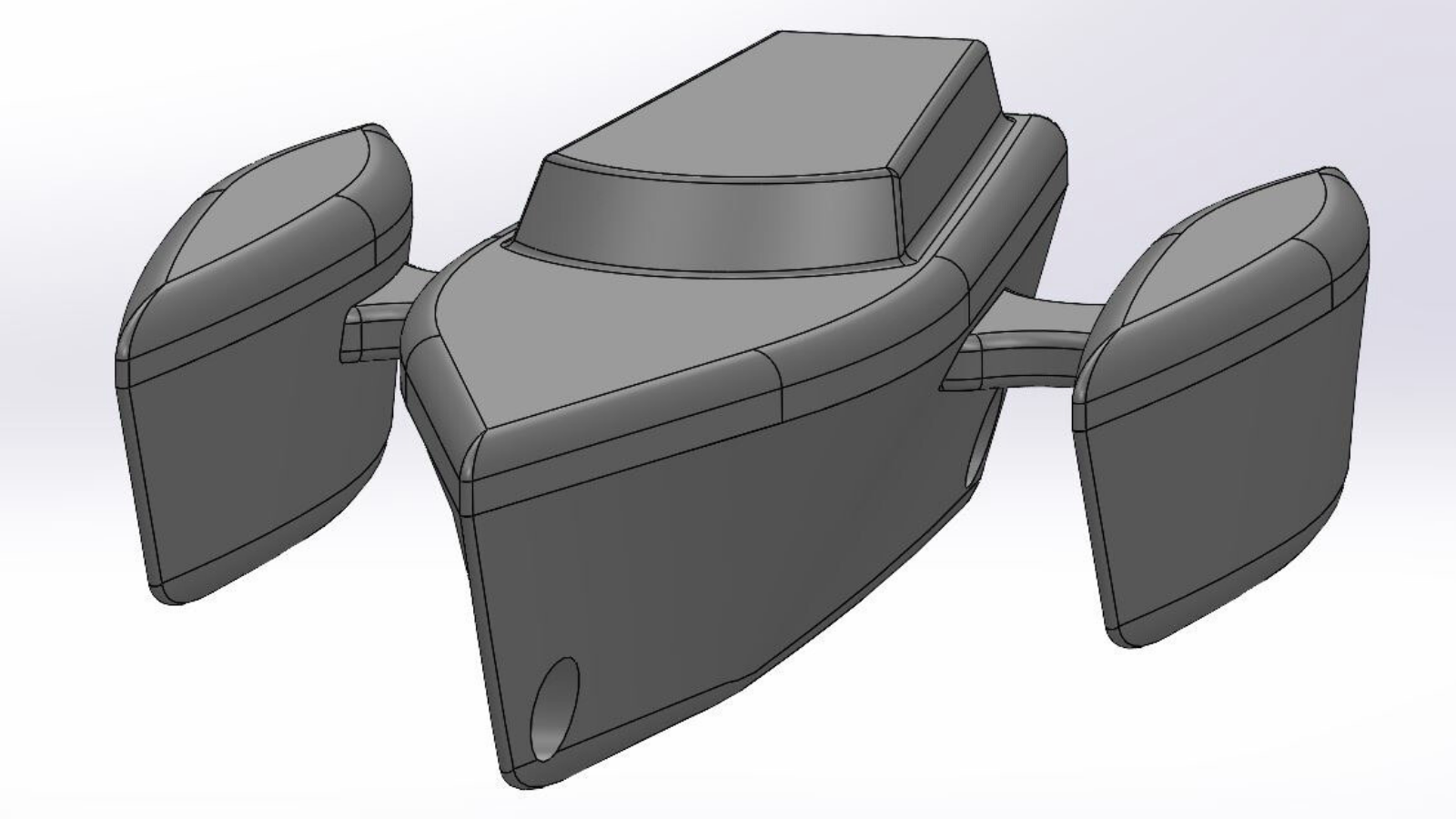

Trimaran platform architecture, carbon fiber structure, and propulsion configuration.

Trimaran Hull & Structure

Our next-generation vehicle concept features a trimaran hull form optimized for low resistance and high stability. The slender center hull minimizes wave-making resistance, while the side hulls (amas) create a wide buoyancy lever for superior initial stability.

Carbon Fiber Construction: Selected for its high rigidity-to-weight ratio and corrosion resistance. The modular internal volume includes watertight compartments for batteries and electronics, ensuring easy service access and precise center-of-gravity management.

- Trimaran Form: Low resistance, high stability.

- Structure: Lightweight carbon fiber composite.

- Specs: ~15 cm Draft, ~35 kg Displacement.

Propulsion Mechanics

The mechanical propulsion layout is designed to combine rapid cruise capability with precise lateral maneuvering. The thruster configuration is physically integrated into the hull to maximize control authority.

Thruster Configuration:

Lateral (Blue Robotics T200): Mounted at the bow and stern for high-precision docking and rotation. Capable of delivering up to 6.7 kgf of thrust at peak load.

Main Drive (Blue Robotics T500): The primary forward propulsion units. Designed for speed, generating up to 16.1 kgf of thrust per unit, enabling high-speed transit and dynamic positioning in strong currents.

- Hybrid Layout: Combines T200 (Precision) and T500 (Power).

- Performance: High thrust-to-weight ratio for agile response.

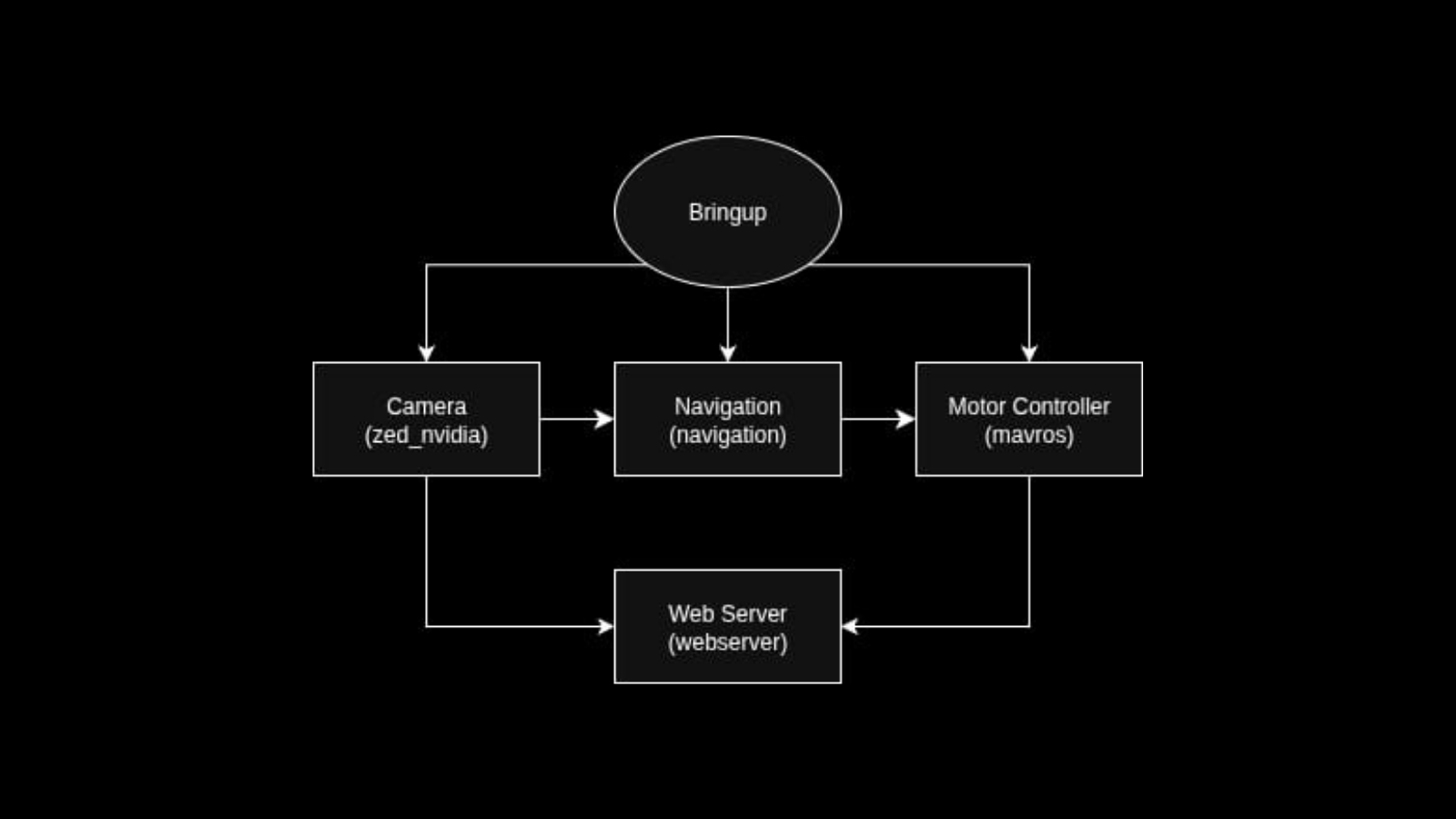

Software Architecture

ROS 2, autonomy, perception, operator interface, and simulation infrastructure.

ROS 2 Architecture, Path Planning & Mission Algorithms

Our ROS 2 (Humble) software stack runs on the NVIDIA Jetson Orin Nano Super and is primarily developed in Python. The system continuously acquires sensor data, processes and logs information in parallel, and executes mission-level decision making. Based on real-time and recorded inputs, the autonomy layer performs path planning and triggers actions according to mission requirements.

- ROS 2 Humble–based modular autonomy architecture

- Parallel sensor processing, logging, and mission execution

- Path planning and mission logic running on Jetson Orin Nano

Perception & Vision

The ZED 2i stereo camera provides synchronized RGB and depth information for buoy and obstacle detection. Depth maps and semantic detections are converted into local cost representations that support safe navigation in structured waterways and competition environments.

- Real-time RGB + depth from ZED 2i stereo camera

- Buoy, obstacle, and marker detection using computer vision pipelines

- Depth-aware risk mapping for navigation and mission logic

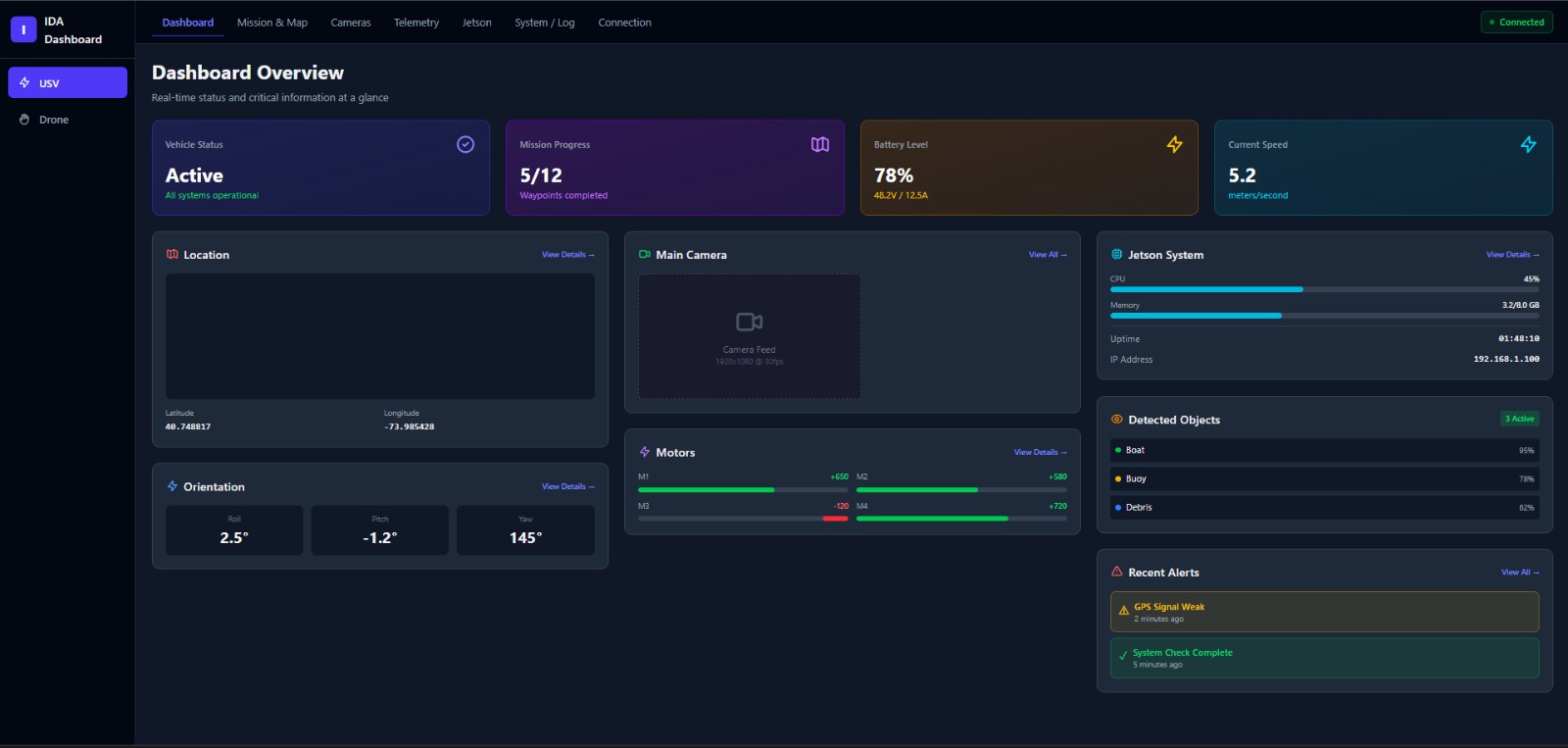

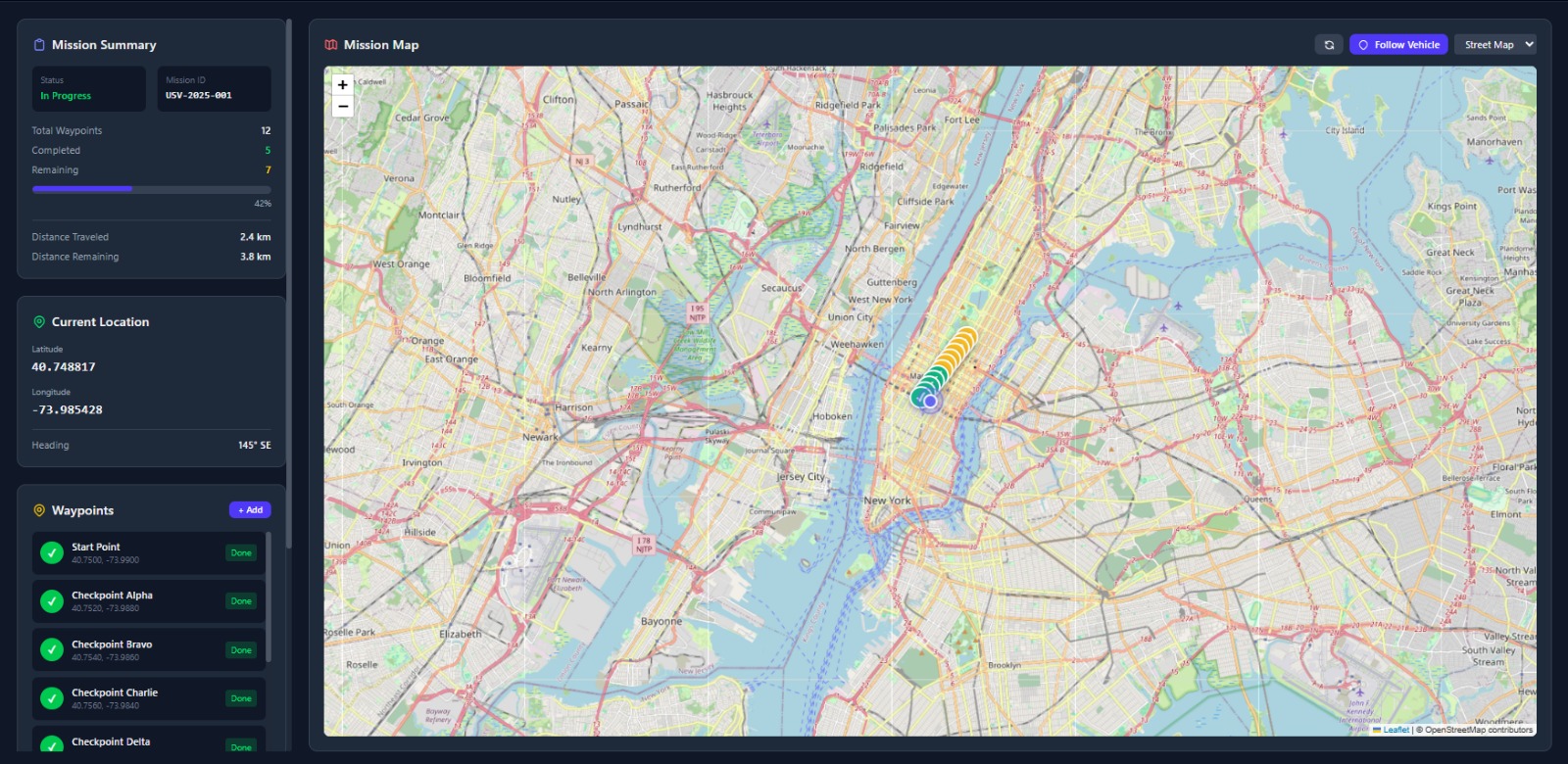

Web-Based Control & Monitoring Interface

The control and monitoring interface runs on the NVIDIA Jetson onboard computer and is accessible through a standard web browser. Developed using HTML, CSS, and JavaScript, it provides real-time visualization of telemetry, mission status, and perception outputs via WebSocket-based communication.

- Runs on Jetson Orin Nano, accessible via web browser

- Real-time telemetry and mission data via WebSocket

- Integrated live camera feed and map-based route tracking

- Extensible architecture for future control and sensor visualizations

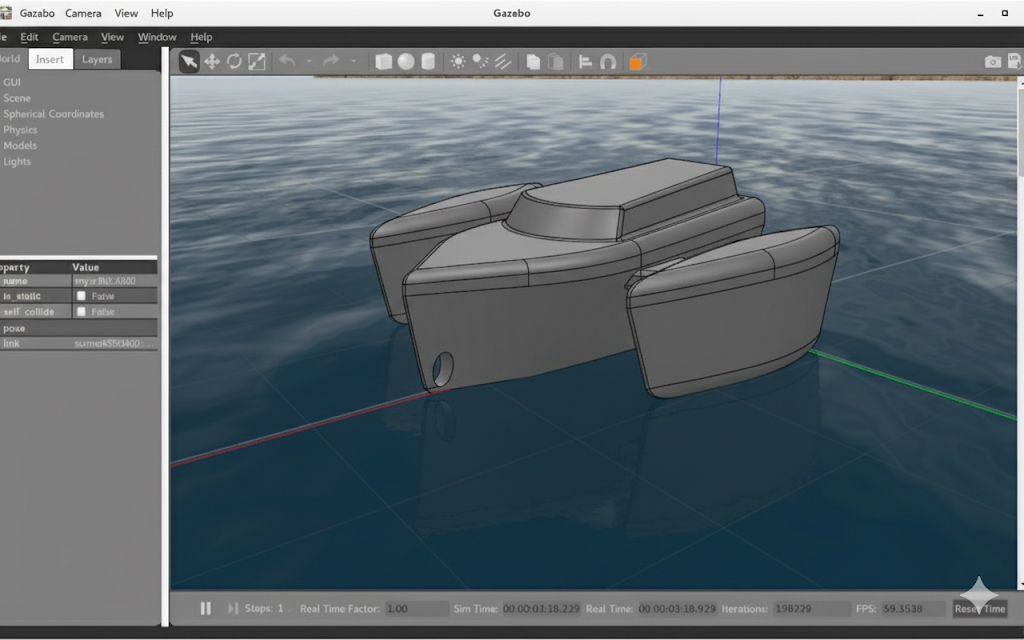

Simulation (Gazebo)

This simulation framework is designed to test and validate stereo camera–based

perception and object detection algorithms developed for the unmanned surface vehicle (USV)

within the Gazebo simulation environment.

A virtual stereo camera integrated into the simulated vehicle provides synchronized image

streams, which are acquired through the ROS 2–Gazebo interface and processed using a

Python-based computer vision pipeline.

The developed object detection models are executed on simulated image data to identify

obstacles and mission-related objects. Depth and distance information extracted from

stereo imagery are utilized to estimate the relative positions of detected objects in the

environment.

This simulation infrastructure enables safe and repeatable testing of algorithms under

different environmental and mission scenarios before deployment on real hardware, allowing

performance evaluation and observation of failure cases without physical risk.

- Synchronized image streaming via a virtual stereo camera in Gazebo

- Real-time image data transfer through ROS 2 integration

- Integration of Python-based object detection algorithms

- Depth and distance estimation from stereo imagery

- Pre-deployment validation of perception algorithms and software components

- Repeatable testing under diverse mission scenarios and environmental conditions

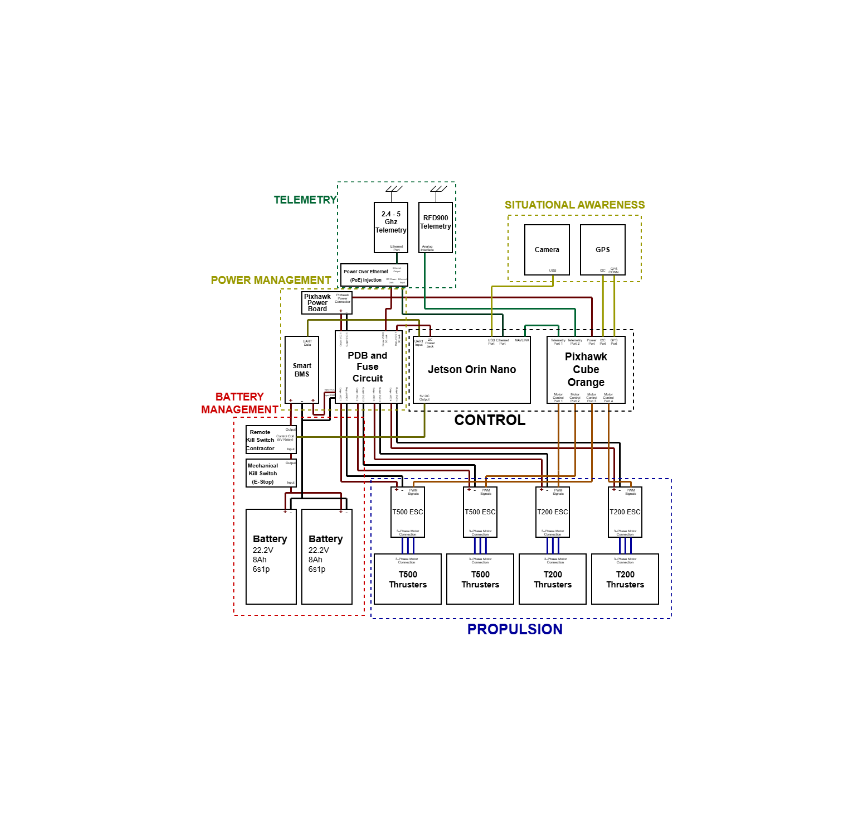

Electrical: Propulsion & Power

High-current propulsion and separated power domains for reliability.

Power Distribution & Propulsion Layout

TALAZ uses Blue Robotics T200 and T500 thrusters to generate precise differential thrust. This configuration enables low-speed maneuverability around docks, gates, and buoy fields while also supporting higher-speed transits when required. Propulsion and compute subsystems are powered by separated battery banks to increase reliability and reduce electrical noise.

- Multiple thrusters driven by dedicated ESCs for fine control

- Independent propulsion battery bank sized for peak current draw

- Isolated low-voltage domain for compute, navigation, and networking

Communication

High-speed links, long-range telemetry, and fault-tolerant communication.

Communication Architecture

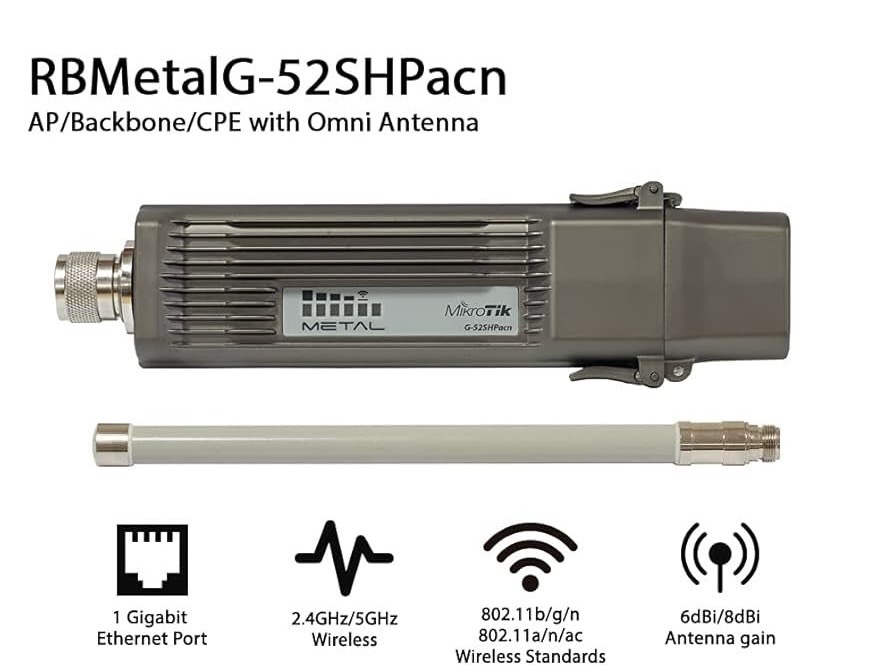

The communication system separates high-bandwidth streams from mission-critical telemetry. MikroTik Metal 52AC access points provide high-speed connectivity for bandwidth-intensive but non-critical data such as video streams. For long-range and mission-critical communication—including GPS and telemetry—RFD900x radio modules are used to ensure reliable operation under degraded link conditions.

- High-speed 5 GHz communication via MikroTik Metal 52AC

- Long-range and mission-critical telemetry via RFD900x

- Separated channels for reliability and fault tolerance

Components

Key components used on the TALAZ USV platform.